As a pioneer in applying modern technology to the Vietnamese packaging production industry, Vipaco is proud to bring customers high quality products that meet European standards. With a professional plastic packaging production process, along with modern production lines and machinery, Vipaco is a reputable and quality plastic packaging manufacturer that all work and partners are looking for. .

When choosing a packaging manufacturer, you will be sure to pay attention to the quality of the company’s production, from which to make the most accurate decision. Because only when applying the production process of quality plastic packaging can the products be guaranteed with quality and design.

Vipaco factory

Vipaco factory

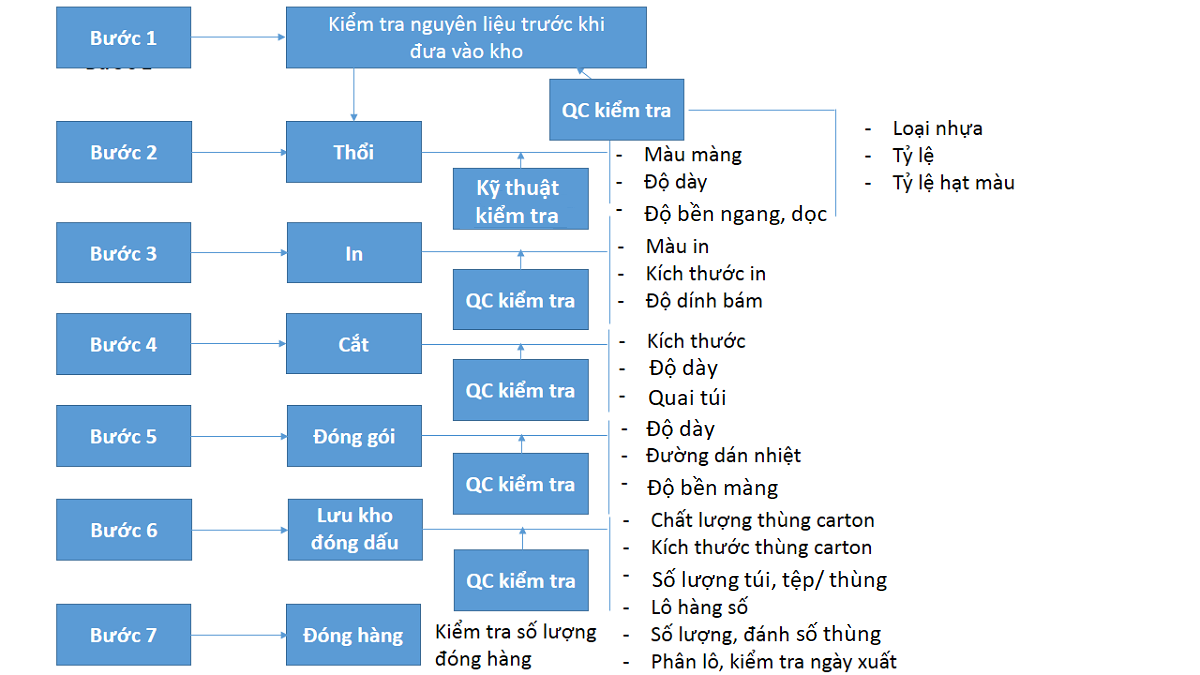

Packaging manufacturing process at Vipaco

As a reputable packaging manufacturer with 15 years of experience, Vipaco has a professional, transparent packaging and is ready for customers to visit production scale.

Vipaco’s packaging production process meets 7 criteria of a professional packaging production process:

- The stages are no longer manual, changing to modern machines to produce products with consistent quality

- The factory is wide, ensuring occupational safety and sanitation

- There is a clear workflow between departments

- The work stages are professionally interconnected

- Stable and high quality raw materials

- Workshops and warehouses are clean, up to 5S standards

- Meet the delivery schedule

In particular, a team of experienced technicians and consultants who understand products well, help businesses easily choose materials, designs and designs that suit customers’ needs. Besides, the price issue also needs to be transparent and create conditions for both sides to cooperate. As for Vipaco’s products, it always meets all requirements of customers:

- Constantly innovating, updating new trends

- Professional design, no duplication

- Production of large orders is still synchronous in design and quality

- The content on the package conveys a clear and complete message

- Printing quality of packaging does not contain impurities and printing ink needs to be clear

Step 1: Input material inspection

The raw materials needed to produce plastic bags are mixed evenly in the mixer including virgin polyethylene resin (HDPE mixed with LLDPE, LDPE mixed with LLDPE, HDPE mixed with MDPE, LLDPE …). All our ingredients are certified for food safety and meet EU and US standard requirements.

Raw material warehouse at Vipaco factory

In addition, depending on the requirements of the customer, some additives can also be mixed such as:

– EPI, D2W, P-life, Reverte or Biocom 1-2% to make biodegradable bags. This type of bag can decompose easily under normal environmental conditions

– Particle color: 3-7% to produce film color: white, blue, orange, yellow, green, black, red

– The anti-stick agent (1-2%) prevents layers of plastic bags from sticking together, especially for bags made from LDPE or LLDPE materials, making bags easier to open.

Ultraviolet (UVI) protection to protect the plastic from ultraviolet radiation. This additive is very useful in the manufacture of bags used in agricultural films.

– For food plastic bags such as freezer bags, transparent strapless plastic bags, flat poly bags, luxury roll bags and luxury plastic bags for famous brands, for example: soft handle bags, hard handle bags, bags drawstring, wavy bags, Vipaco always uses 100% PE virgin plastic to give the best quality bags, durable, smooth and beautiful.

Step 2: Blowing film (extruding film)

After mixing well, the mixture will be processed into a high temperature melting form suitable for each type of resin. The mixture is blown out in the form of a tube full of air blown from the air streams, then blown in the roll bar. This step is very important as it can affect the firmness, thickness and transparency of the film.

EVOH 5-layer blowing machine from 600mm to 1600mm, automatic oil oil control, made in Europe at Vipaco factory

EVOH 5-layer blowing machine from 600mm to 1600mm, automatic oil oil control, made in Europe at Vipaco factory

With simple printed plastic bags of 1-4 colors, we can print in the blowing process, which is called inline printing. Particularly for high-end bags that print more than 4 colors or print complex images, the blown roll will be transferred to a separate printer, called offline printing.

In this step, the workers or quality control staff must carefully control for the film to carry the correct thickness, the film is even and beautiful.

Step 3: Print

This process is mainly used for shopping bags, companies will design the company logo, brand name, product information and print it on the bag surface … When we receive a printed order, we will set the printing axis (printing axis from the company as the axis). The print roller will be placed in the printer. Each printing color will be made a separate axis and placed separately on the printer system. With modern and high-tech printers, Vipaco can print 100% plastic plastic bags covering from 1 to 8 colors.

Automatic printer from 6 to 8 colors, printing size up to 1200mm at Vipaco factory

Step 4: Cut

The plastic rolls are fed into the cutting workshop to cut into bags with different handles and shapes. Currently, the Vipaco factory has 49 automatic cutting machines, including thermal cutters, high speed automatic roll cutting machines, high speed T-shirt bag cutting machines, roll cutting machines … Different product categories: foam bags, foam roll bags, mango seed bags, food bags, drawstring trash bags, bags, T-shirts …

Step 5: Packing

Plastic bags after being cut into each piece will be packed according to customer requirements. About 20-100 pieces are packed in a bag (can be printed or not), then packed into a carton.

Vipaco’s quality control (QC) process is top notch. Our workers and technicians are well trained before going to work. At each stage of production, we have 3-4 responsible product quality inspectors to make sure the products in each process meet the customer’s requirements.